In the realm of industrial manufacturing and construction, efficiency is key to success. One often overlooked but crucial aspect of this efficiency is the handling and deployment of fabrics, textiles, and materials used in various applications. Fabric roll out equipment plays a pivotal role in optimizing these processes, offering solutions that streamline operations and enhance overall productivity.

What is Fabric Roll Out Equipment?

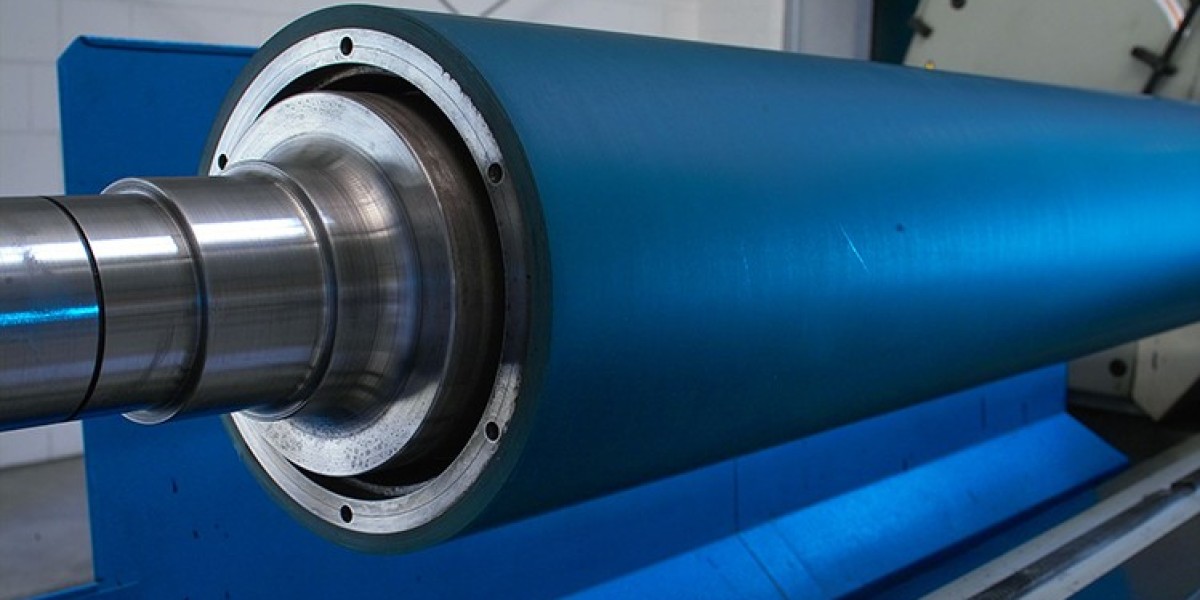

Fabric roll out equipment encompasses a range of machinery designed to facilitate the handling, cutting, and deployment of large rolls of fabric or materials such as carpets, vinyl, paper, and more. These machines are specifically engineered to manage the challenges associated with unwieldy rolls, ensuring precise handling and cutting while minimizing waste and labor costs.

Types of Fabric Roll Out Equipment

Roll Handling Systems: These systems are designed to safely transport and position rolls of fabric or materials within manufacturing facilities. They typically include features such as automated roll lifting, rotation capabilities, and precise positioning to facilitate easy loading onto processing equipment.

Roll Cutting Machines: Essential for accurate and efficient cutting, these machines range from simple manually operated units to fully automated systems. They are equipped with sharp blades or laser cutting technology to ensure clean cuts without fraying, reducing material waste and improving production speed.

Roll Spreading Machines: Used primarily in industries like apparel manufacturing and upholstery, roll spreading machines automate the process of laying out fabric layers for cutting or sewing. They ensure uniform tension and alignment of fabric rolls, optimizing downstream processes and reducing labor-intensive tasks.

Roll Inspection Systems: Quality control is critical in industries where material defects can lead to costly rework or customer dissatisfaction. Roll inspection systems utilize sensors and imaging technology to detect flaws, inconsistencies, or damage in rolls before they are processed further, ensuring only high-quality materials are used.

Benefits of Fabric Roll Out Equipment

Increased Efficiency: By automating handling, cutting, and inspection processes, fabric roll out equipment reduces manual labor requirements and accelerates production cycles.

Improved Accuracy and Precision: Machines designed for cutting and spreading ensure consistent results, reducing errors and material wastage.

Enhanced Workplace Safety: Automated handling systems minimize the risk of injuries associated with manual lifting and moving heavy rolls.

Cost Savings: Reduced material waste, improved efficiency, and decreased labor costs contribute to overall cost savings for manufacturing operations.

Scalability: Modular designs and customizable features allow fabric roll out equipment to adapt to varying production demands and material types, supporting scalability in manufacturing operations.

Applications Across Industries

Fabric roll out equipment finds application across diverse industries including:

Textile Manufacturing: From apparel to technical textiles, efficient handling and cutting are crucial for maintaining quality and meeting production targets.

Automotive and Aerospace: Upholstery and interior components require precise cutting and handling of materials such as leather and fabric.

Construction and Flooring: Carpets, vinyl, and other flooring materials benefit from accurate cutting and laying processes.

Conclusion

In conclusion, fabric roll out equipment represents a cornerstone of modern industrial efficiency, offering solutions that optimize handling, cutting, and deployment of materials across various sectors. As industries continue to prioritize productivity and quality, investing in advanced fabric roll out technology proves essential for staying competitive in today's market.

Whether in textile manufacturing, automotive upholstery, or construction materials, the benefits of these specialized machines are clear: they streamline processes, reduce waste, and elevate overall operational efficiency, paving the way for enhanced profitability and customer satisfaction in industrial operations.