Introduction

Welcome to our comprehensive guide on rotary vane vacuum pump. In this article, we delve into the intricacies of these remarkable devices, exploring their functionality, applications, advantages, and key features. Whether you're a seasoned professional in the field of vacuum technology or someone seeking to expand their knowledge, you'll find valuable insights within these pages.

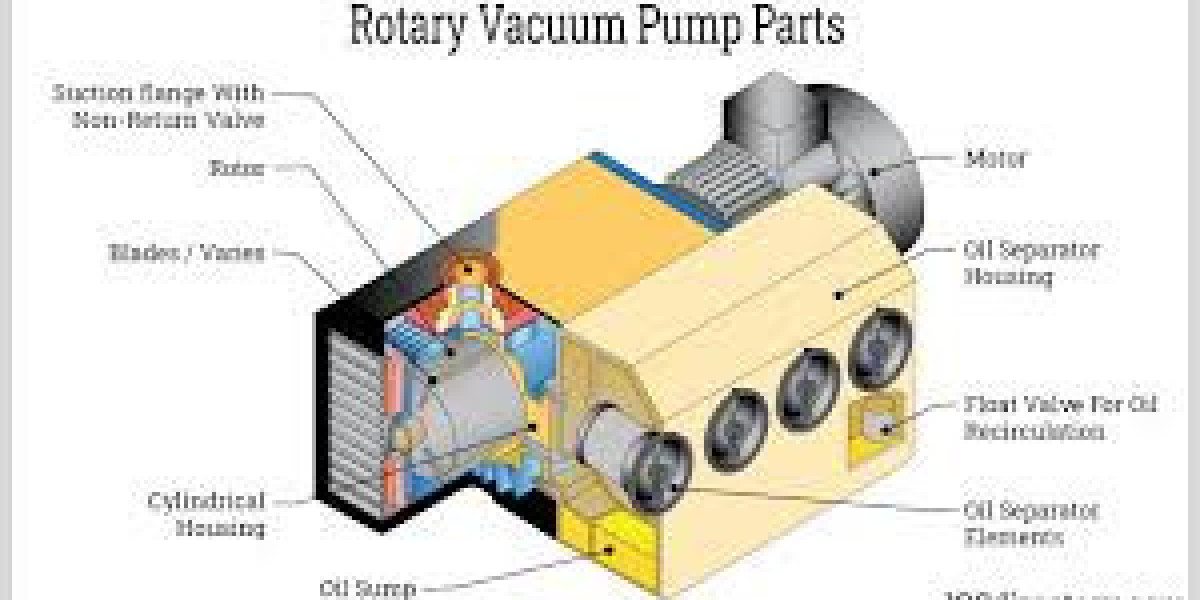

Understanding Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are mechanical devices designed to create a vacuum within a closed system by removing air or gas molecules. They operate on the principle of positive displacement, utilizing rotating vanes or blades to compress and exhaust air. This process results in the generation of a vacuum, making these pumps indispensable in a wide range of industrial, scientific, and commercial applications.

Applications

Industrial Applications

In the industrial sector, rotary vane vacuum pumps play a crucial role in various processes, including:

- Vacuum Packaging: Ensuring product freshness and extending shelf life.

- Material Handling: Facilitating the transportation of materials in manufacturing environments.

- Chemical Processing: Handling corrosive gases and vapors safely and efficiently.

- Medical Equipment: Powering devices such as vacuum ovens and freeze dryers.

Scientific and Research Applications

In scientific laboratories and research facilities, rotary vane vacuum pumps are utilized for:

- Analytical Instrumentation: Supporting instruments like mass spectrometers and electron microscopes.

- Vacuum Deposition: Creating thin films of materials for semiconductor and optical applications.

- Space Simulation: Mimicking outer space conditions for testing aerospace components.

Commercial Applications

Beyond industrial and scientific realms, rotary vane vacuum pumps find application in various commercial sectors, including:

- HVAC Systems: Assisting in the evacuation and maintenance of air conditioning and refrigeration systems.

- Printing and Paper Handling: Enabling the removal of air from paper feed systems in printing presses.

- Waste Management: Supporting processes such as vacuum sewage systems and waste oil recovery.

Advantages of Rotary Vane Vacuum Pumps

Efficient Operation

Rotary vane vacuum pumps offer high efficiency, providing reliable vacuum generation with minimal energy consumption. Their robust design ensures long-term performance and durability, making them a cost-effective solution for diverse applications.

Versatility

One of the key advantages of rotary vane vacuum pumps is their versatility. They can handle a wide range of gases and vapors, making them suitable for diverse process requirements. Additionally, they are available in various sizes and configurations to meet specific application needs.

Low Maintenance Requirements

Thanks to their simple design and fewer moving parts, rotary vane vacuum pumps require minimal maintenance. Routine tasks such as lubrication and filter replacement contribute to extended service life and operational reliability.

Key Features

Vane Configuration

The design of the vanes in a rotary vane vacuum pump significantly impacts its performance. Factors such as vane material, length, and arrangement influence parameters such as vacuum level, flow rate, and ultimate pressure.

Sealing Mechanism

Effective sealing is critical for maintaining vacuum integrity and preventing air leakage. Rotary vane vacuum pumps employ various sealing mechanisms, including oil-sealed and dry-running options, each offering distinct advantages based on application requirements.

Cooling Systems

To prevent overheating and ensure continuous operation, rotary vane vacuum pumps incorporate efficient cooling systems. These may include air-cooled or water-cooled configurations, designed to dissipate heat and maintain optimal operating temperatures.

Conclusion

In conclusion, rotary vane vacuum pumps represent a versatile and efficient solution for vacuum generation across a wide range of applications. With their robust design, high performance, and minimal maintenance requirements, they continue to play a vital role in industries ranging from manufacturing and research to healthcare and commercial sectors.

Read More :

| https://www.becker-international.com/in/1788/rotary-vane-vacuum-pumps-oil-lubricated.htm |