In the realm of industrial operations, precision and accuracy are paramount. From manufacturing to logistics, the measurement of weight plays a crucial role in ensuring efficiency and quality control. At the heart of this process lie industrial scales, an indispensable tool that has undergone a remarkable evolution over the years.

Understanding Industrial Scales

Industrial scales are specialized instruments designed to measure and weigh heavy loads accurately. They come in various forms, including bench scales, floor scales, truck scales, and crane scales, each tailored to specific industrial applications. These scales are utilized across diverse sectors, from agriculture and manufacturing to transportation and logistics.

The Analog Era: A Foundation of Reliability

Historically, industrial scales were predominantly analog devices, relying on mechanical components such as springs and levers to measure weight. While these scales provided a foundation of reliability, they were not without limitations. Analog scales were susceptible to wear and tear, calibration issues, and lacked the precision demanded by modern industries.

The Digital Revolution: Enhanced Precision and Efficiency

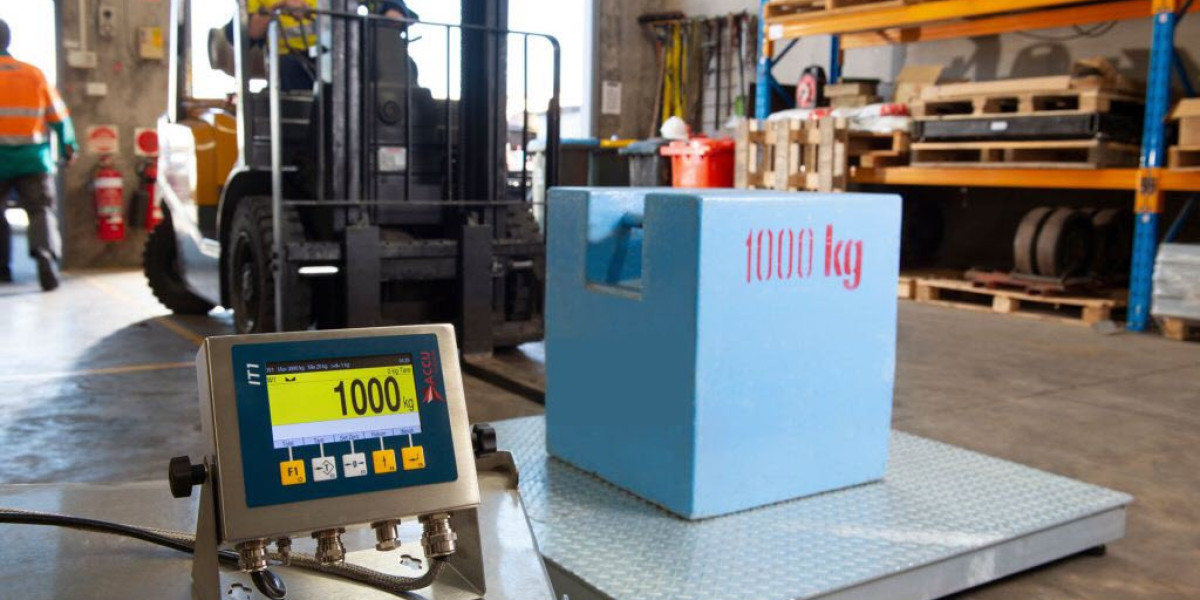

The advent of digital technology revolutionized the landscape of industrial weighing. Digital industrial scales leverage advanced electronic components, including load cells and microprocessors, to deliver unparalleled accuracy and efficiency. These scales offer features such as digital readouts, tare functions, and connectivity options for data logging and integration with enterprise systems.

Key Advantages of Digital Industrial Scales

Precision: Digital scales offer precise measurements, minimizing errors and ensuring consistency in weight readings.

Versatility: With programmable settings and customizable features, digital scales can adapt to a wide range of industrial applications.

Efficiency: Digital scales streamline weighing processes, enabling faster throughput and enhanced productivity in industrial environments.

Data Management: Integration with software systems allows for seamless data collection, analysis, and reporting, facilitating better decision-making and compliance with industry standards.

The Role of SEO in Promoting Industrial Scales

In today's digital age, the visibility of industrial scale manufacturers and suppliers relies heavily on effective search engine optimization (SEO) strategies. By strategically incorporating relevant keywords such as "industrial scales" into website content, blog posts, and product descriptions, businesses can enhance their online presence and attract organic traffic from potential customers.

Conclusion

Industrial scales represent a critical component of modern industrial processes, facilitating accurate measurement and weight management across diverse sectors. The transition from analog to digital technology has significantly improved the precision, efficiency, and versatility of these essential tools. By embracing digital innovation and leveraging SEO strategies, industrial scale manufacturers and suppliers can effectively reach their target audience and showcase the value of their products in today's competitive marketplace.

FAQ'S

1. What are industrial scales used for?

Industrial scales are used to measure the weight of heavy objects or materials in various industrial settings. They are essential for tasks such as inventory management, quality control, shipping and receiving, and production processes.

2. What types of industrial scales are available?

There are several types of industrial scales available, including:

Bench scales

Floor scales

Truck scales

Crane scales

Platform scales

Counting scales

Pallet scales

Each type is designed for specific applications, with varying weight capacities and features.

3. How accurate are industrial scales?

The accuracy of industrial scales depends on factors such as the type of scale, calibration, and the quality of the components. Digital industrial scales tend to offer higher accuracy compared to their analog counterparts, with some models capable of providing precise measurements down to fractions of a pound or kilogram.

4. How often should industrial scales be calibrated?

Industrial scales should be calibrated regularly to ensure accurate measurements. The frequency of calibration depends on factors such as the usage environment, the level of accuracy required, and any regulatory requirements. Many industries follow calibration schedules recommended by manufacturers or regulatory agencies.

5. Can industrial scales be connected to other systems or devices?

Yes, many modern industrial scales come equipped with connectivity options such as Wi-Fi, Ethernet, or USB ports, allowing them to be connected to computers, printers, barcode scanners, or enterprise systems. This connectivity facilitates data logging, integration with inventory management software, and real-time monitoring of weighing processes.

6. How do I choose the right industrial scale for my application?

Choosing the right industrial scale involves considering factors such as:

Weight capacity: Ensure the scale can accommodate the heaviest objects you need to weigh.

Environment: Consider factors such as temperature, humidity, and exposure to dust or chemicals.

Accuracy requirements: Determine the level of precision needed for your weighing tasks.

Features: Evaluate additional features such as digital readouts, tare functions, and connectivity options based on your specific needs.

7. Are industrial scales subject to any regulations or standards?

Yes, depending on the industry and the intended use of the scales, there may be regulations or standards that govern their design, calibration, and usage. Industries such as manufacturing, pharmaceuticals, and food processing often have specific requirements for weighing equipment to ensure product quality, safety, and compliance.

8. How do I maintain industrial scales for optimal performance?

Regular maintenance is essential to ensure the optimal performance and longevity of industrial scales. This may include:

Cleaning the scale surface and components regularly to prevent buildup of debris or contaminants.

Checking and calibrating the scale according to the manufacturer's recommendations or regulatory requirements.

Inspecting for signs of wear, damage, or malfunction and addressing any issues promptly.

Following proper handling and usage guidelines to prevent damage to sensitive components.