Custom carts for material handling are often overlooked. However, they are indispensable assets, wielding the power to enhance operational efficiency and streamline material flow across diverse industries. Despite their ubiquity, organizations using custom carts encounter challenges in identifying optimal applications, leading to overreliance on forklifts, manual handling and suboptimal inventory management.

Custom carts are enjoying increased demand with the growth of manufacturing companies all over the world, and for good reason.

Custom carts are in high demand for several reasons, primarily due to their ability to address specific and unique requirements in various industries. The customization of carts allows businesses to optimize their material handling processes by tailoring the design, dimensions, features, and functionalities to meet the exact needs of their operations.

This level of customization ensures that the carts seamlessly integrate into specific workflows, allowing for increased efficiency and productivity. Industries with diverse and specialized requirements, such as manufacturing, healthcare, and logistics, often find standard carts inadequate for their tasks.

What are custom material handling carts?

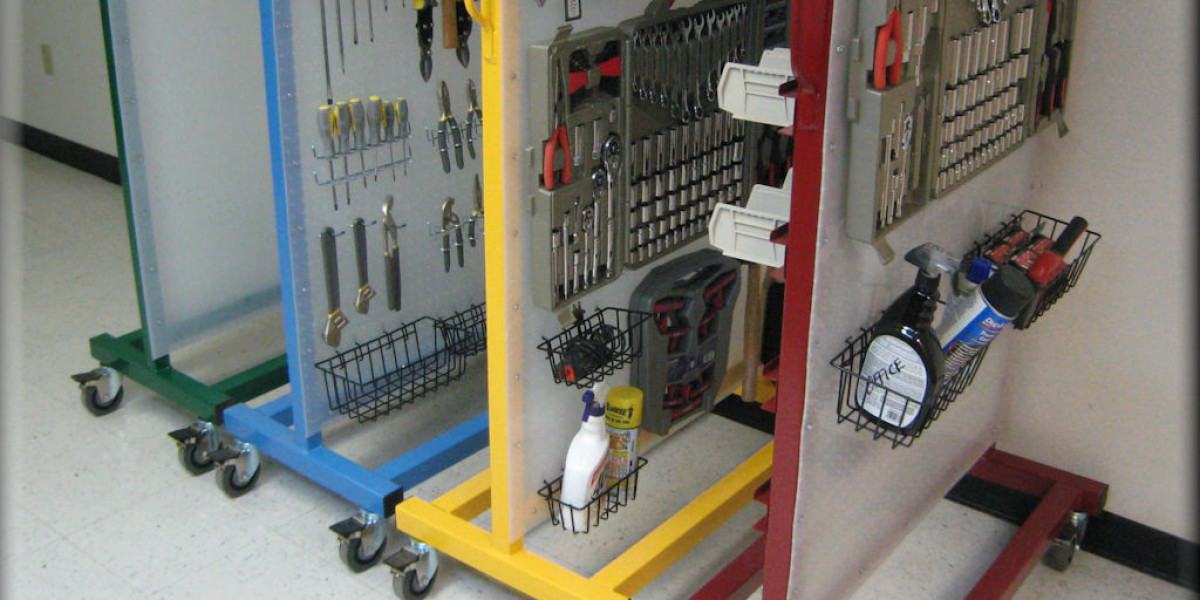

Custom material handling carts are specialized carts designed and tailored to meet the specific needs and requirements of a particular industry, application or organization. Unlike standard, off-the-shelf carts, custom carts are built with unique features, dimensions and functionalities to address specific challenges and optimize material handling processes in a more efficient and tailored manner.

Some of the key features of a typical custom cart include:

- Specific Dimensions: Custom carts are designed with precise dimensions to accommodate the size and shape of the materials they are intended to transport. This ensures optimal use of space and prevents unnecessary wastage. It is important to determine one’s requirements and then move ahead with the choice of custom carts.

- Specialized Materials: The choice of materials for cart construction can be customized based on factors such as load capacity, durability requirements, and environmental conditions. For example, carts used in corrosive environments may be constructed with materials resistant to corrosion.

- Unique Configurations: Custom carts can be configured with specialized features such as adjustable shelving, compartments, racks, or slots to securely hold and transport specific types of materials. This helps in preventing damage and improving the overall efficiency of material handling processes.

- Integrated technologies: Depending on the industry or application, custom carts may incorporate technology solutions such as RFID systems, GPS tracking or automation features to enhance tracking, monitoring and control of materials during transportation.

- Ergonomic Design: Consideration for ergonomics is crucial in custom cart design, ensuring that the carts are user-friendly, easy to maneuver, and promote a safe working environment for operators.

- Customized Load Capacity: The load capacity of custom carts is tailored to the specific requirements of the materials being transported. This ensures that the carts can handle the weight and volume of the materials without compromising safety.

- Branding and Identification: Custom carts can be designed with branding elements and identification features, making it easy for operators and workers to distinguish between different carts and materials. This aids in efficient sorting and organization.

- Compliance with Regulations: Depending on the industry, custom carts may need to comply with specific regulations or standards. Designing carts with these regulations in mind ensures that they meet safety and operational requirements.

Conclusion

Custom carts emerge as indispensable assets, tailoring efficiency to the unique demands of diverse industries. With precision in dimensions, specialized materials, and integrated technologies, these carts optimize material flow, enhance safety, and offer a tailored solution to the challenges faced in manufacturing plants.