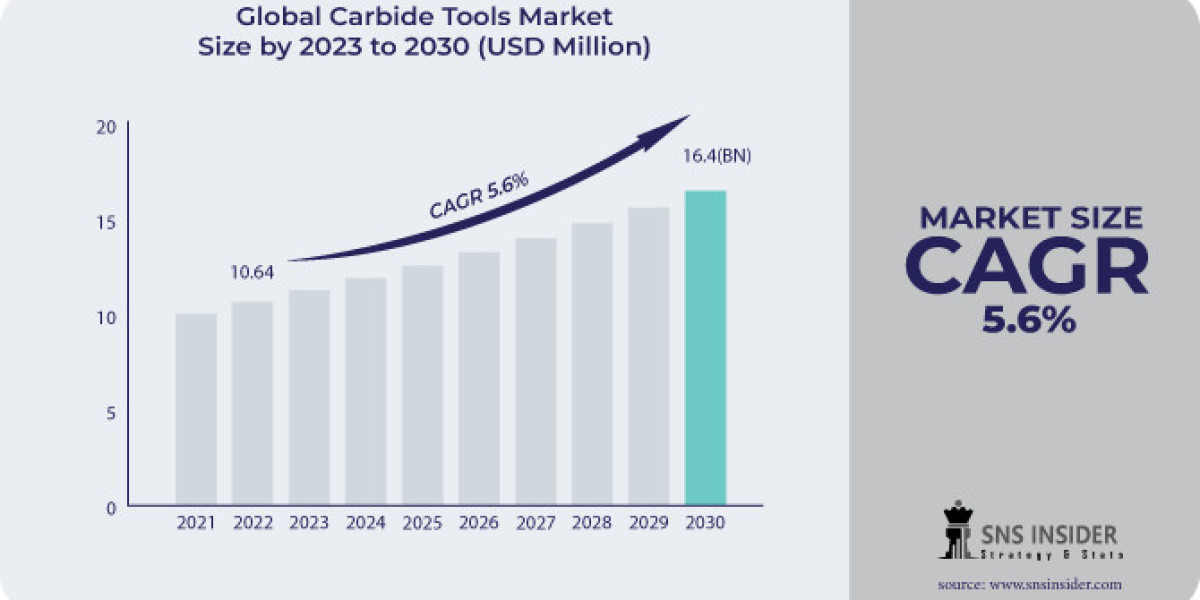

The Carbide Tools Market, estimated at USD 10.64 billion in 2022, is poised for significant growth, with projections indicating an increase to USD 16.4 billion by 2030. This trajectory reflects a noteworthy Compound Annual Growth Rate (CAGR) of 5.6% during the forecast period from 2023 to 2030.

Carbide tools, also known as cutting tools with carbide tips or cemented carbide, have become integral in various industrial applications, particularly in metal fabrication, automotive, construction, furniture, and industrial machinery. These tools are manufactured using tungsten and carbide powder, resulting in materials with three times the hardness of steel. Additionally, carbide tools exhibit heat resistance, rapid machining capabilities, shorter recycling times, and cost-effectiveness.

In the industrial sector, carbide-cutting tools or inserts have been widely used over the past few decades. They find application in heavy-duty equipment such as drilling machines, CNC machines, lathe machines, and milling machines, serving as essential cutting tools. The robust properties of carbide, including hardness and resistance to heat and wear, make these tools highly suitable for demanding machining processes across various industries.

The increase in demand for carbide tools from diverse industries contributes to the global market expansion. As manufacturing processes become more sophisticated and industries seek efficiency and precision, the adoption of carbide tools continues to grow. The forecasted CAGR underscores the industry's anticipation of sustained growth, reflecting the essential role that carbide tools play in modern machining and manufacturing. The period from 2023 to 2030 holds promise for the Carbide Tools Market as it aligns with the evolving needs of industries and advancements in cutting tool technology.

Key Players

The major key players are OSG Corporation, Sandvik AB, Makita Corporation, Plansee Group, Kennametal Inc., Sumitomo Electric Industries Ltd., Guhring Ltd.Fullerton Tool Company Inc.YG-1 Co Ltd, Allied Machine & Engineering Corp, others.

Get a Sample Report of Carbide Tools Market @ https://www.snsinsider.com/sample-request/3871

KEY MARKET SEGMENTATION

- Product type

- Drilling Tools

- Milling Tools

- Turning Tools

- Others (Taps & Dies, Reamers)

- Coating Type

- Coated

- Non-coated

- Configuration

- Hand Based

- Machine Based

DRIVERS

1. Increasing Demand for High Productivity in Industry and Manufacturing:

The industrial and manufacturing sectors are witnessing a growing demand for high productivity. This demand is particularly prominent in industries such as automotive, aerospace, industrial, and construction. Carbide-cutting tools play a crucial role in precise machining and manufacturing, responding to the expansion of these sectors. Carbide tools are favored for their increased productivity and longer tool life compared to traditional cutting tools, making them attractive to producers aiming to boost output. In precision-demanding sectors like aerospace and defense, carbide tools are preferred for maintaining tight tolerances.

OPPORTUNITY

1. Expansion to Developing Nations:

For suppliers of carbide tools, exploring opportunities in developing nations with growing manufacturing industries, especially in regions like Asia-Pacific, holds the potential to create new business prospects.

2. Sustainability Initiatives for Carbide Tool Manufacturing:

Implementing sustainability initiatives, including recycling programs and ecologically friendly manufacturing methods for carbide tools, aligns with environmental objectives. This approach can attract consumers who prioritize environmentally conscious practices.

3. Integration with Industry 4.0 Technology:

Enhancing monitoring, maintenance, and overall tool efficiency can be achieved through the integration of Industry 4.0 technologies, such as IoT sensors and data analytics. This modernization contributes to improved operational efficiency in the manufacturing and machining processes.

Get This Exclusive Report of Carbide Tools Market @ https://www.snsinsider.com/checkout/3871

Table of Contents

1. Introduction

1.1 Market Definition

1.2 Scope

1.3 Research Assumptions

2. Research Methodology

3. Market Dynamics

3.1 Drivers

3.2 Restraints

3.3 Opportunities

3.4 Challenges

4. Impact Analysis

4.1 Impact of the Ukraine- Russia War

4.2 Impact of Ongoing Recession

4.2.1 Introduction

4.2.2 Impact on major economies

4.2.2.1 US

4.2.2.2 Canada

4.2.2.3 Germany

4.2.2.4 France

4.2.2.5 United Kingdom

4.2.2.6 China

4.2.2.7 japan

4.2.2.8 South Korea

4.2.2.9 Rest of the World

5. Value Chain Analysis

6. Porter’s 5 forces model

7. PEST Analysis

8. Carbide Tools Market, by Product Type

8.1 Drilling Tools

8.2 Milling Tools

8.3 Turning Tools

8.4 Others (Taps & Dies, Reamers)

9. Carbide Tools Market, By Coating Type

9.1 Coated

9.2 Non-coated

10. Carbide Tools Market, By Configuration

10.1 Hand Based

10.2 Machine Based

11. Regional Analysis

.... Continued

To know more, Get Access to Sample Report @ https://www.snsinsider.com/sample-request/3871